Precision Engineering and Machining

With a fully experienced and dedicated workforce, up to date equipment for CNC milling/turning and a single point of contact you are always assured of a rapid and flexible response to all your enquiries. As an ISO 9001:2008 registered company we are ever mindful of our need to maintain a high level of excellence in all that we do. In support of this we have embarked on a programme of development of both our capacity in terms of machinery as well as our capability in terms of people development.

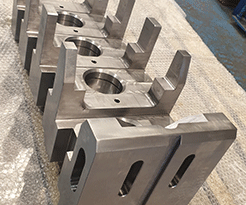

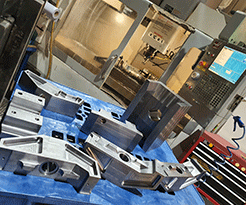

CNC Machining

We have invested in the best CNC machine centres on the market including HAAS and Hurco. This allows us to offer a fast turnaround on milled and turned parts to any design specification. Our CNC service is fast, efficient and very cost effective.

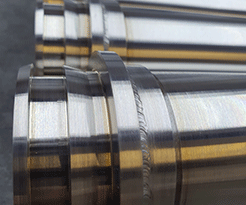

Manual Machining

While the latest technology is important, there are still certain situations that require conventional manual machining. Projects like screw threading, and machining extra-large items such as long rollers (up to 8ft, need a manual service by skilled operators. We still have a high demand for manual machining for bespoke one-off projects.

Threading

We are one of the few remaining engineering firms to offer both traditional and trapezoidal threading services. Threading using manual machining techniques is fast becoming a highly specialist skill.

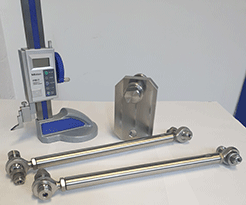

Honing

Constructed using an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it along a controlled path.

For pipe polishing or for any piece of metal that needs a silk quality finish, we can offer you a fast and competitively priced service.

Stainless Steel

Here at RAF General Engineering we pride ourselves on the quality of our stainless-steel work. We are extremely proud of our extensive facilities that allow us to carry out a wide range of projects. We have recently upgraded our plant and equipment so we can handle up to 15 tonnes in weight.

- Unit 1 – 5000sq foot engineering machine shop including 6 machining centres, 3CNC lather, 2 manual lathes and 2 milling machines. Modern CNC 3D CADCAM computer software allows us to manufacture to a global level. Our own in-house inspection facilities and offices and trade counter suppling power transmission equipment, bearings, oil and lubricants for both industry and public.

- Unit 2 - 5000sq foot Stainless Steel Welding and Fabrication facility with dedicated, professional welding bays offering TIG and MIG welding services with nuclear, oil and gas industries. .

Stainless steel facilities are vital in the nuclear and chemical industries. Our 1000sq ft stainless steel area is guaranteed free of cross-contamination.

The work we do

At RAF General Engineering Ltd we offer high quality, fully comprehensive services that cater to all varieties of industry. These include, but are not limited to:

- Sheet metal work

- Piping

Pipe Fitting

Installing, repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work involves selecting and preparing pipe or tubing, joining it together by various means, and the location and repair of leaks.

We can make or repair any form of metal piping or tubing systems that convey liquid, gas, or solid materials. We can hand machine threads or manufacture bespoke designs with our CNC systems.

Our pipework can be supplied anywhere in the UK and we offer competitive prices and a fast turnaround.

- Pipelines & pipework installations

- No limit to size

- Specialist fabrications

- Welded or screwed format

- Pipeline testing

- Pressure/non-pressure vessel manufacture

Spark Eroding

- Spark eroding or electro metal disintegration is for the removing of broken bolts, studs, drills, taps or extractors. The removal of broken drills, taps, extractors, bolts etc.

- We achieve this by creating an electric spark between the broken item and the electrode which is held in a vibrating head. The spark at the tip of the electrode and the item to be removed reaches almost 5000 degrees Centigrade. Flooding with coolant creates a thermal shock, reducing the heated material of the broken item to powder which is flushed away.

- We offer a fast cost effective service for spark eroding, guaranteed.

Wire Eroding

- Wire EDM; Electrical Discharge Machining, is a process that uses electric current and fine wire to cut and shape metals, metal alloys and other conductive materials. It leaves a smooth surface that usually requires no further finishing or polishing.

- Our high precision CNC driven Wire EDM facility is capable of producing precision, high aspect ratio apertures and features that could not be achieved using other metal cutting techniques

- The process is highly accurate and repeatable. It produces exceptionally precise, parallel sidewalls, allowing stacking when machining multiple parts from sheet material. Taper cuts, free curves and complex shapes can be achieved simply by rotating the axis of the wire before or during the process.

- Further finishing is generally unnecessary and parts may be used immediately in assembly, minimising the time between design and delivery.

Non Ferrous Metal

- Non-ferrous metals are used due to having such as low weight and are also highly used in the iron and steel industries.

- We have undertaken several research and development projects for the nuclear industry in the development of components using non ferrous metals.

- We have 'clean machines' and can work in gold, silver, aluminium, brass, lead and copper.